Chinese wholesale Safety Tape For Clothing - Transparent silk screen printing heat transfer reflective sheeting – Alsafety

Chinese wholesale Safety Tape For Clothing - Transparent silk screen printing heat transfer reflective sheeting – Alsafety Detail:

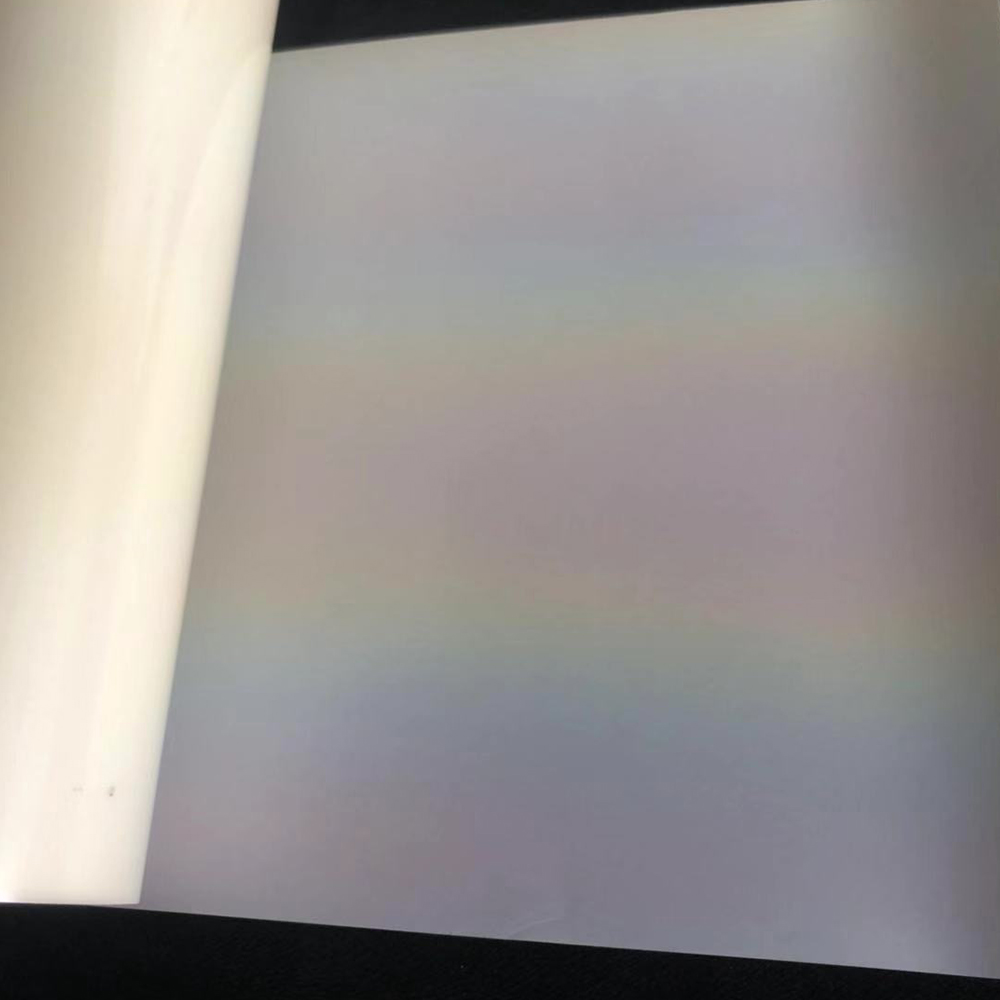

The heat transfer reflective film is used at a hot pressing temperature of 140-160 degrees, a pressing time of 8-10 seconds, and a pressure of 3-4 kilograms. The company’s reflective film has high reflective brightness and is washable.

In case of cloth biting when peeling off the pet surface facial mask, it is recommended to use the company’s self-adhesive reflective film. If the cloth base is water repellent fabric, it is recommended to use the company’s water repellent reflective film. The heat transfer reflective film is to carve the pattern, tear off the excess part, turn the pattern into hot, and then tear off the PET film after cooling.

It is widely used in clothing, bags, shoes and other textile fabrics; For example: Sportswear: number and trademark, basketball, football, bicycle clothing, sneakers, swimsuits, other elastic and blended fabrics; Personalized clothing: personalized T-shirts, advertising shirts, advertising umbrellas, aprons, hats, travel bags of travel agencies, numbers and logos of factories and schools.

Heat transfer reflective film that needs to be engraved or cut in the process of thermal transfer. Under the joint action of heat and pressure, it is separated from the carrier film together with the release layer, and is firmly transferred on the surface of the substrate.

The heat transfer reflective film is divided into elastic and micro elastic. The basic reflective film is added with anti splashing, adhesive and anti sublimation functions.

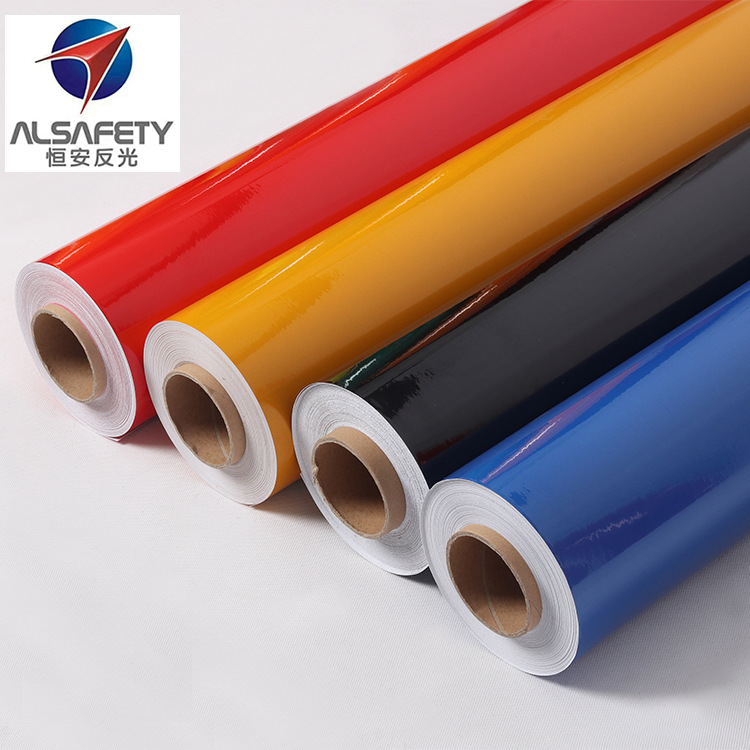

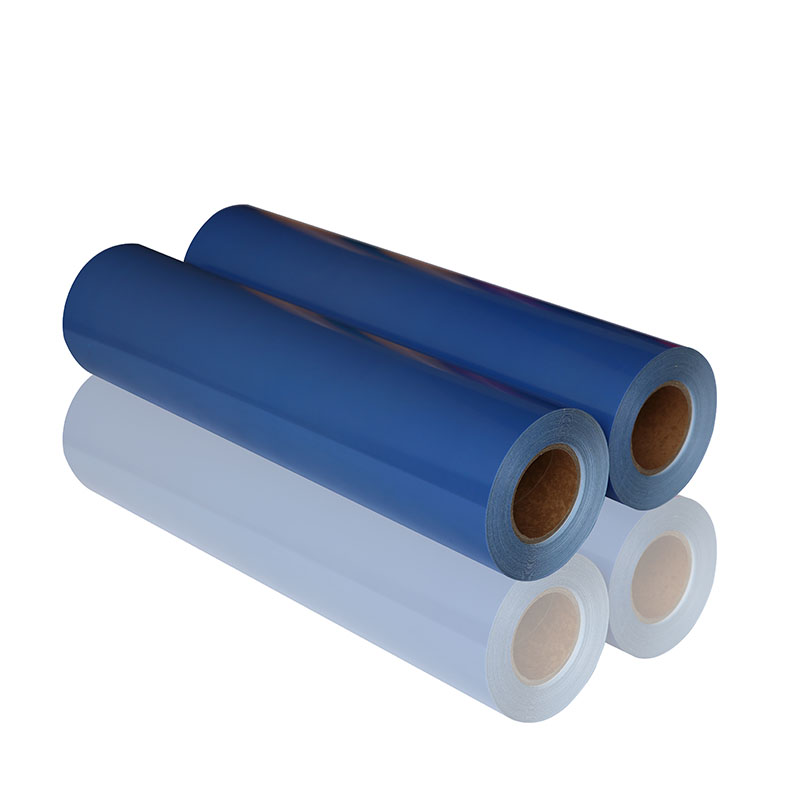

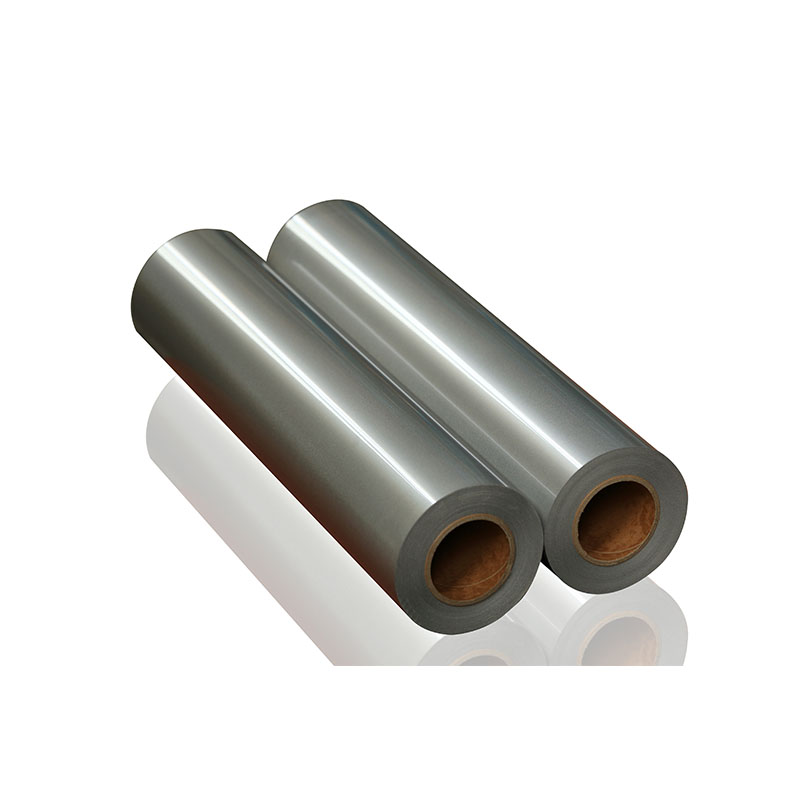

The company’s reflective film has more than 20 colors, and the common specifications are 50cm * 50m and 60cm * 50m, 1.2m * 50M / roll and 1m * 50M / roll. Other specifications can be customized. It can also be cut according to the needs of customers.

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for Chinese wholesale Safety Tape For Clothing - Transparent silk screen printing heat transfer reflective sheeting – Alsafety , The product will supply to all over the world, such as: Seattle, Sacramento, Guyana, Our staffs are adhering to the Integrity-based and Interactive Development spirit, and the tenet of high quality Quality with Excellent Service. According to the needs of every customer, we give customized & personalised services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!